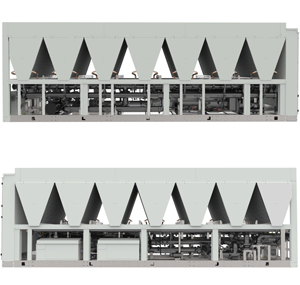

TurboChill™ and TurboChill™ FreeCool Spray Evaporator

The TurboChill™ spray evaporator range has been designed with the future of refrigerants in mind, utilising R1234ze (GWP 7) and R513A (GWP 573). The range uses spray flooded evaporator technology, which allows the system charge to reduce by over 50% compared to a standard flooded heat exchanger. Savings of up to 70% refrigerant charge can be made in the evaporator alone.

Up to twice as much free-cooling as equivalent thermosiphon products

Three BREEAM points in recognition of low global warming impact

Intelligent, self-optimising compressors enable 30 – 100% variable speed control

Unbeatable efficiencies at part load.

Compressors present near silent, oil-free operation

More than 166 models available to choose from

The TurboChill™ delivers an industry-leading energy efficient cooling solution with capacity to deliver up to twice as much free-cooling as equivalent thermosiphon products. The addition of low GWP refrigerants R1234ze (GWP 7) and R513A (GWP 573) makes the TurboChill™ a highly sustainable option, which automatically receives three BREEAM points in recognition of its low global warming impact.

R1234ze readily breaks down in the atmosphere within a very short lifetime (16.4 days) and is rated by the International Panel for Climate Change (IPCC) with a 100-year GWP lower than 1, which performs better than CO2.

All units incorporate the latest Centrifugal TurboCor compressor technology including the low capacity TG230 compressor which uses R1234ze. These intelligent, self-optimising compressors enable 30 – 100% variable speed control with respect to maximum capacity and working conditions for tighter setpoint management and unbeatable efficiencies at part load.

The intelligent, self-optimising compressors present near silent, oil-free operation and ultra-efficient, variable speed control. This allows the TurboChill™ Spray Evaporator to match load requirements exactly and enables selection of the optimum model, in terms of efficiency, sound level, footprint and price, for each individual application.

The TurboChill™ Spray Evaporator range offers increased flexibility and choice with more than 166 models available to choose from. 52 of these models have been specifically developed for use with the low Global Warming Potential (GWP) refrigerant R1234ze, whilst 78 TurboChill™ models from the range combine the latest compressor technology with the power-saving benefits of free-cooling.

TurboChill™ Spray Evaporator matches load requirements exactly and enables selection of the optimum model, in terms of efficiency, sound level, footprint and price, for each individual application.

TurboChill™ FreeCool Spray Evaporator – ultimate efficiency

For the ultimate in energy efficient chiller solutions, the new TurboChill™ FreeCool Spray Evaporator combines the unparalleled efficiency of centrifugal Turbocor compressor technology, with the power saving benefits of free-cooling. The oil-free operation of the revolutionary Turbocor compressor allows infinitely variable speed operation giving exact capacity match and using substantially less power at part load. Units within this range are Ecodesign Tier 2 compliant for both process (SEPR) and comfort cooling (SSCEE) applications. Please refer to the technical manual, website, or your Airedale account manager for full details

| Chiller | Capacity | Max EER | Max ESEER | Refrigerant | Compressor Type | Circuits |

| TurboChill air cooled Spray Evaporator | 195 – 1550kW | 4.18 | 5.66 | R513A (TT300, TT350)

R1234ze (TG230, TG310) |

Oil free Centrifugal compressors

|

Single

Dual |

| TurboChill FreeCool Spray Evaporator | 225 – 1650kW | 4.18 | 5.66 | R513A (TT300, TT350)

R1234ze (TG230, TG310) |

Oil free Centrifugal compressors

|

Single

Dual |