Understanding Coolant Distribution Units (CDUs) for Liquid Cooling Efficiency

As data centers evolve to meet increasing demands, especially with the rise of high-density computing, liquid cooling has emerged as a critical solution. Coolant Distribution Units (CDUs) are pivotal in managing liquid cooling systems, ensuring data centers operate efficiently and safely.

As data centers evolve to meet increasing demands, especially with the rise of high-density computing, liquid cooling has emerged as a critical solution. Coolant Distribution Units (CDUs) are pivotal in managing liquid cooling systems, ensuring data centers operate efficiently and safely.

Airedale’s Coolant Distribution Units provide effective thermal management by precisely controlling the delivery and return of coolant to the IT racks. These units are vital components in secondary cooling loops, which isolate the critical IT infrastructure from the facility’s primary water supply. By using CDUs, data centers can mitigate the risk of leaks and maintain optimal temperatures, all while improving energy efficiency and embracing a hybrid approach to data center thermal management.

How Coolant Distribution Units Work

At the heart of the liquid cooling system, CDUs regulate fluid volumes, flow rates, and temperatures. This approach’s primary benefit is precise control, ensuring that only the necessary amount of coolant is delivered, while maintaining the correct pressure and driving the compute’s efficiency and performance.

Additionally, CDUs integrate sophisticated monitoring systems that detect leaks early, allowing for immediate intervention and reducing downtime risks. These units are also compatible with a variety of coolants, including water/glycol mixtures, ensuring versatility for multiple data center environments.

The Benefits of Coolant Distribution Units

Our CDUs are designed for direct-to-chip and hybrid cooling environments, including rear door heat exchanger (RDHx) applications, which facilitate simplistic, modular, efficient and performance-driven deployments.

Engineered for Excellence

The CDU features built-in redundant pumps, filtration, and intuitive controls, ensuring reliable performance and precise coolant delivery to handle load fluctuations.

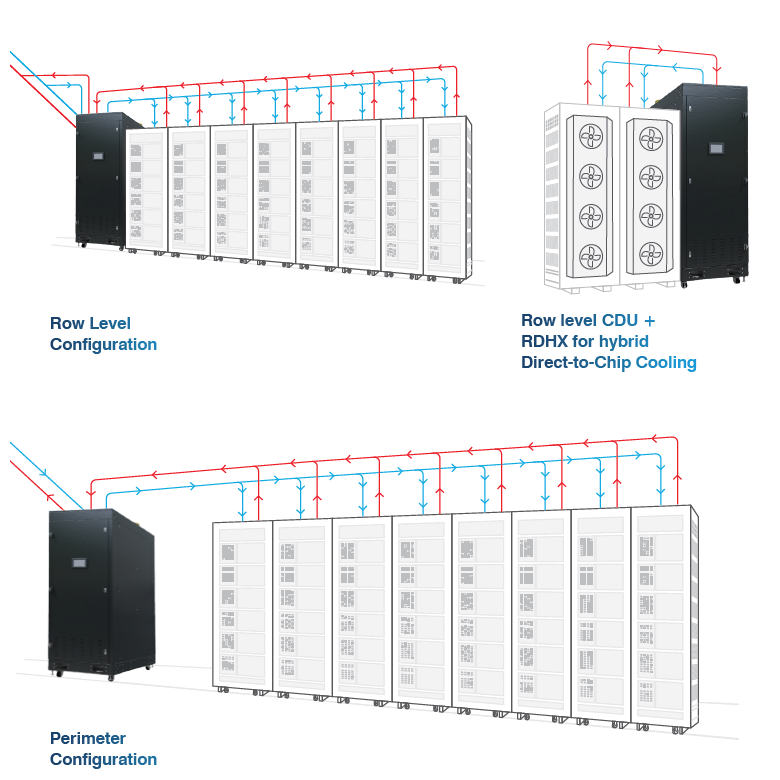

Flexible Configuration

Choose from standard models or collaborate to create custom configurations tailored to your needs.

Global and Modular Design

The CDU’s adaptable design allows for deployment in various project locations, ensuring effective thermal management.

Seamless Integration

Compatible with existing infrastructure, the CDU integrates easily into in-rack server profiles or facility rooms, providing a dynamic and future-proof thermal management solution.

1 MW Capacity

The compact design maximizes power density for liquid or hybrid cooling systems.

Redundant Systems

N+1 pumps, drives, and filters allow for maintenance without disrupting operation.

Enhanced Filtration

Extra-large filter bodies increase filtration area, reducing contamination risks. Standard filtration is 50μ, and optional 25μ filtration is available on the secondary Technology System Loop (TCS) .

Easily Accessible

Front-accessible components include control panels, VSDs, expansion tanks, and filter cartridges for simplified maintenance.

System Configuration

Safety Concerns Considered

Introducing fluid close to critical IT equipment is a risk many data center operators are wary of. Our CDUs have integrated safety features that protect, detect, and mitigate fluid leaks, ensuring unrivalled peace of mind and an efficient, reliant, and resilient safe supply to critical IT equipment.

The Benefits of Liquid Cooling

Liquid cooling can provide several high-level benefits, including improved thermal management and heat transfer. This is especially true in high-performance computing environments, where liquid cooling efficiently absorbs and dissipates heat directly from the chip, resulting in lower operating temperatures, reduced thermal throttling, and enhanced performance.

Liquid cooling typically consumes less energy than traditional air cooling, leading to lower power costs and the potential for reduced environmental impact. Liquid cooling can also increase the reliability and longevity of IT equipment. By maintaining optimal temperatures, liquid cooling can reduce the risk of overheating and thermal fatigue, ultimately extending the lifespan of the components.

Furthermore, CDUs’ efficiency means they manage heat and can offer a greener alternative. Integrated into the CDU setup, the potential for heat recovery enables the reuse of waste heat in other parts of the facility or district heating schemes, contributing to a more sustainable operation. In this instance, it is essential to assess the project goals, as there can be a trade-off between sustainability goals for heat reuse and performance at the chip level, which can alter a system’s operating envelope.

Supporting a Hybrid Future

The future of data center cooling is increasingly hybrid, incorporating a mix of air and liquid. In this evolving landscape, the crucial role of a CDU in supporting hybrid applications cannot be overstated. The trend for hybrids is driven by the need for more efficient and sustainable solutions in managing the heat generated by high-performance servers, including next-generation CPUs and GPUs, and equipment in data centers. These components push the thermal design powers (TDPs) at the chip, resulting in the densification of rack loads.

Air cooling, a well-proven method that is cost-effective and easy to implement, traditionally utilizes fans and air circulation to dissipate heat. However, as data centers become denser with powerful hardware and high-performance computing, the limitations of air cooling become more apparent. While you can push the envelope of air cooling with operating envelopes, containment and spot cooling via targeted CRAC, InRow and RDHX, there is a clear limit on a rack-by-rack basis.

Liquid cooling, alternatively, involves circulating coolants like water or refrigerants to absorb and remove heat from equipment directly. The liquid cooling method is more efficient at dissipating heat than air cooling, allowing for more precise temperature control and improving performance and energy savings.

The reason why we see hybrids as the future is that not all computing is high-performance computing. From our customer base, we see pockets of high-performance computing using increasingly hot GPUs. However, traditional IT loads are still growing and will sit on standard IT hardware, such as e-commerce, TV streaming, e-mail, and video calls. By combining air and liquid cooling techniques in a hybrid approach, data centers can cater to multiple applications and customers and achieve optimal cooling performance, all while minimizing energy consumption and environmental impact. They can also design for space and tackle the solutions using a modular ramp.

The hybrid solution enables data center operators to balance the benefits of air and liquid cooling based on the specific needs of their infrastructure, making it a versatile and effective choice for the future of data center cooling. It is not taking out and ripping up all of your infrastructure in existing facilities, where the building is already in situ, and the infrastructure is already in place. It applies hybrid additions to densify areas of the Data Center. There is a combination of the two and a ramp to get to the higher density, which is where a hybrid system approach is so compelling, and Airedale by Modine can provide a best-fit solution.

Why Airedale by Modine?

With 50 years of experience in cooling technology, we deliver complete solutions that prioritise performance and efficiency, optimized via controls and in-territory aftermarket support. Our CDUs have been designed in consultation with industry professionals and engineered to handle the demands of modern data centers, ensuring reliable operation even as computing densities rise. Each unit is designed with advanced safety features, including automatic shutoff valves and real-time monitoring, to keep your IT equipment secure.

By integrating our CDU into your liquid cooling strategy, you ensure the best thermal management and a solution that adapts to the future of high-density computing.

At Airedale by Modine, we are technology lead, people first – engineers first, second and third. We are deeply committed to understanding the problems we are solving, ensuring that we deliver high-performance, next-generation systems that truly meet the market’s needs.

We drive towards mutual trust, establishing trust through reliability, integrity, and accountability. We aim to put the work in upfront to develop lasting partnerships, as that is the best way to ensure everyone gets what they want out of the relationship and consistently meets and exceeds requirements.

Our approach to managing the whole thermal management chain from inside to outside the facility is comprehensive and consultative. We align to a shared vision and goals, defining what good looks like and then relentlessly delivering it. We will consistently articulate a shared vision and align the customer’s goals to ensure mutual understanding and commitment to the partnership’s success, leveraging each partner’s strengths, expertise, and resources to enhance the partnership’s capabilities and competitiveness.

Above all, we are collaborative. We will always strive to work together, seamlessly, increasing productivity and innovation, aligning to stakeholders values and culture, with mutual respect. Our commitment to collaboration is unwavering, as we believe it is the key to mutual success. We value our partners and consider them integral to our mission.

View our CDU product page