![]()

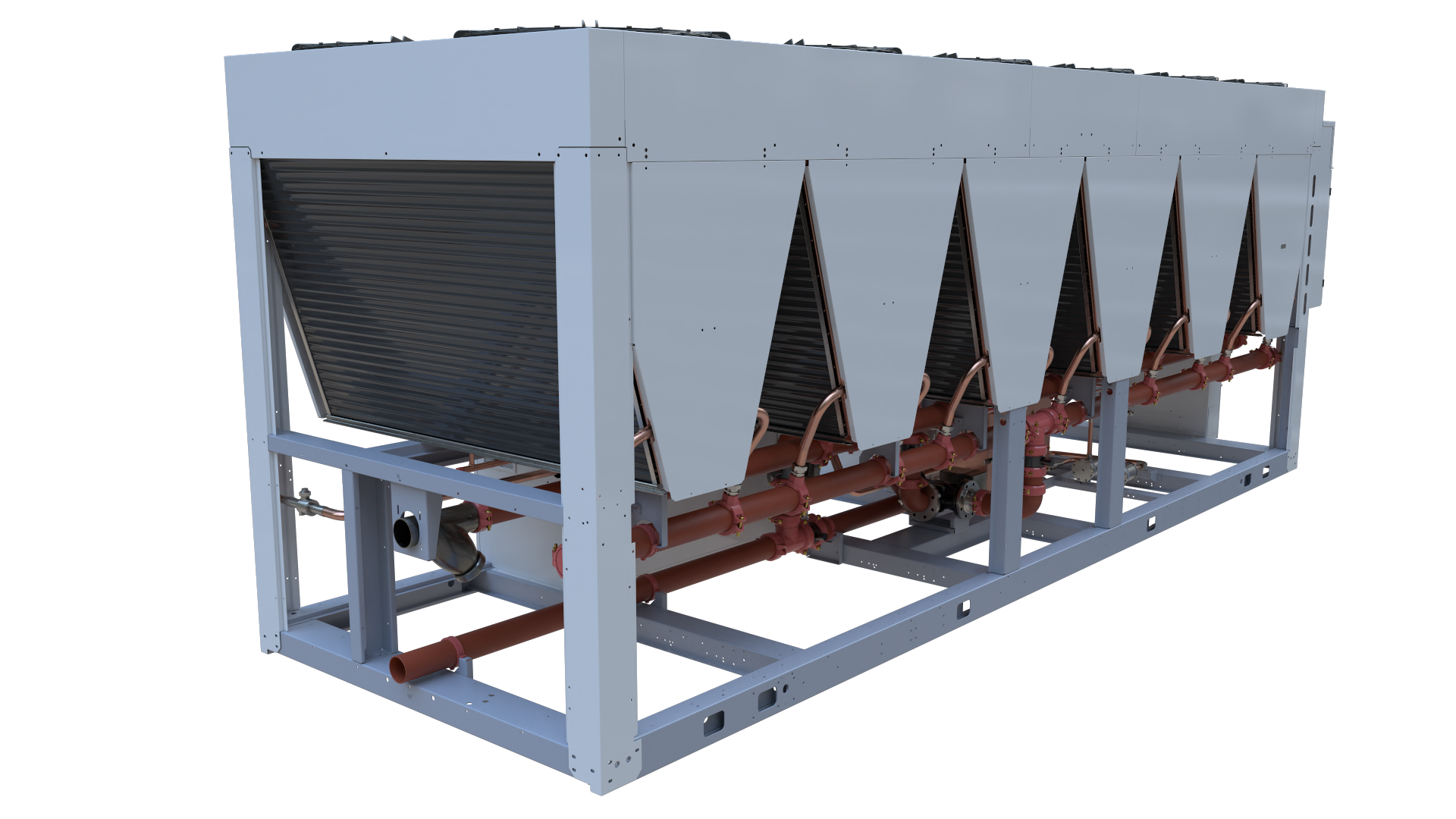

DeltaChill DCSTM takes our standard DeltaChillTM chiller to the next level.

Optimised for data centre environments, DeltaChill DCS benefits from enhanced free cooling technology to maximise efficiencies in high temperature settings.

DeltaChill DCS, like all DeltaChill chillers, is an air cooled scroll chiller, that operates using either refrigerant R410A, or the lower GWP refrigerant R32 (GWP 675). Available with a wide span of cooling capacities, from 110 to 1010kW, this extremely energy efficient yet compact chiller combines quiet, cost effective scroll compressors with the latest fan technology, applied in a modular V-frame coil design.

Microchannel heat exchangers lift efficiency even higher, whilst still minimising space claim. With approximately 300 models available, it offers exceptional flexibility, tailored exactly to your application, allowing unit selection to be optimised for efficiency or footprint.

At a glance:

- 110 to 1100kW

- Approx 300 models

- R32 (GWP 675) model available for reduced GWP

- Quiet, cost effective scroll compressors

- Latest fan technology applied in a modular V-frame coil design

- Microchannel heat exchangers lift efficiency higher

- Free cooling functionality offers significantly reduced running costs

- Low sound ranges: Quiet (R) and Extra Quiet (X)

- Sequenced scroll compressors minimise sound and allow capacity to more precisely match the application

- Electronic Expansion Valves increase ESEER by 30%

- Leak detection as standard on R32 model

- EC Fans as standard