Coil Corrosion Protection

Key components of air conditioning systems such as heat exchangers, evaporator coils and condenser coils in external chillers, condensers and dry coolers are at continuous risk of corrosion due to weather conditions and pollution.

Extend the life of heat exchangers in your HVAC equipment

Key components of air conditioning systems such as heat exchangers, evaporator coils and condenser coils in external chillers, condensers and dry coolers are at continuous risk of severe corrosion due to weather conditions and pollution.

Corrosion is the number one cause of efficiency loss in the heat exchanger.

Heat exchangers and coils are made using aluminum, which is relatively corrosion resistant even without any type of coating. However, the harsh conditions in certain air conditioning applications often require additional protection, these include:

• Offshore applications

• Coastal applications

• Power plants

• Industrial environments

• Urban dense applications

• Any area to have high levels of airborne pollutants

There are many airborne substances and atmospheric influences that shorten the life of heat exchangers; these include corrosive salts, acids, bases, and/or other chemicals.

Long lasting anti-corrosion treatment

Airedale provides a long lasting anti-corrosion treatment for heat exchangers. This preventative process seals off the heat exchanger from the environment, without affecting heat transfer and pressure drop.

The process can be applied to new units at our factory in Leeds as well as on-site via our Coil Protection service through our nationwide network of expert service engineers. It can also be applied to both Airedale’s and third party manufacturer’s equipment on site and can be applied to any type of heat exchanger/coil.

Why protect?

• It can triple the lifetime of the heat exchanger

• Prevents early deterioration, capacity loss and the need for coil replacement

• Potential annual savings of up to 30% on energy costs

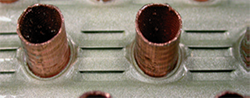

Treated vs. Untreated

Plans available

Choose from three comprehensive standard packages; Protect, Refresh or Renew. Alternatively, you can tailor a maintenance package to suit your individual requirements.

Protect

• For coils/units that are 3-4 years old

• Carry out standard clean and apply treatment to any untreated coils

Refresh

• For coils/units that are 4-8 years old

• Carry out standard clean and ‘top up’ treatment to already treated coils

Renew

• For coils/units that are 8+ years old

• Carry out a deep clean and apply treatment to coils

Need a quote? Speak with your sales engineer or contact us.

COMMISSIONING

We provide a full commissioning service carried out by professionally trained, experienced engineers to ensure your equipment runs efficiently in order to optimise its performance.

SERVICE & MAINTENANCE

Our AC service plans offer a great preventative air conditioning maintenance service solution to improve system resilience and increase the longevity of your cooling system.

ENERGY UPGRADES

Replacing AC fans with EC fans allows optimisation of cooling systems for ultimate energy efficiency, potentially reducing energy usage by up to 70%.