FAQ

Frequently Asked Questions on the Shift from R-410A to R-454B Refrigerant in the Industry

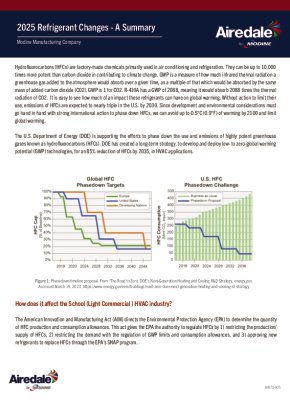

The U.S. Department of Energy (DOE) is supporting the efforts to phase down the use and emissions of highly potent greenhouse gases known as hydrofluorocarbons (HFCs). DOE has created a long-term strategy to develop and deploy low- to zero-global warming potential (GWP) technologies. This initiative aims for an 85% reduction in HFC use in HVAC applications by 2035. The American Innovation and Manufacturing Act (AIM) directs the Environmental Protection Agency (EPA) to regulate HFC production and consumption. The phasedown of the HFCs will challenge the availability of replacement refrigerants to service the industry.

An A2L refrigerant is a type of refrigerant classified for its low flammability and low toxicity. These refrigerants are designed to have a lower Global Warming Potential (GWP) compared to traditional refrigerants, making them more environmentally friendly. They are increasingly used in air conditioning and refrigeration systems to meet stricter environmental regulations. Two common refrigerants are R-32 and R-454B. R-32 has a GWP of 675 while R-454B has a GWP of 466. For comparison, the non-A2L refrigerant R-410A has a GWP of 2,088.

In November 2022, it was announced that the EPA will enforce a GWP limit of 700 on new production by January 1, 2025, for residential and light commercial air conditioning and heat pump systems. This limit will be enforced on VRF (Variable Refrigerant Flow) systems a year later, on January 1, 2026. By imposing such limits, the goal is to reserve the limited supply of HFCs for existing installations.

For Modine and other peers to start manufacturing products to go to market, the refrigerant system needs to use A2L refrigerants, such as the two named above; R-32 and R-454B. After significant evaluation of both refrigerants, Modine selected R-454B for the following reasons:

- It provides excellent performance, comparable to R-410A.

- It has a lower GWP than R-32. This lower GWP value provides environmental benefits and is significantly lower than the upcoming EPA enforced GWP limit of 700.

- R-454B has been selected by a large number of OEM’s, which will help ensure the refrigerant is readily available and contractors are familiar with the refrigerant.

For the Airedale School Products that are DX split units, the condensing unit supplied by others must be an R-454B unit. Our design and testing was specific to R-454B refrigerant and is labeled as such on the product serial plate.

There are specific requirements that the customer and/or contractor need to consider in their design and installation. It is important to review and follow the guidance and requirements in the Installation Manuals for both the condensing unit by others and the Airedale unit ventilator product. For the Airedale unit ventilator products, there is information in the manuals that covers topics including piping practices, minimum room sizing, charging and evacuation, etc.

Airedale School Products have achieved certification under the UL-60335 safety standards in 2024 and are currently completing tests to update our file for use with A2L refrigerants. Manufacturing of the initial products using the new refrigerant is slated to begin in the fourth quarter of 2024, with a complete transition expected by January 1, 2025.

As a mildly flammable refrigerant, the introduction of A2L refrigerants necessitates updates to building codes across various levels of government to ensure safe use. These updates will incorporate standards from UL 60335-2-40, ASHRAE 34, and ASHRAE 15. Manufacturers will handle equipment safety, while contractors and technicians will manage site-specific safety protocols, including space analysis and safety training aligned with EPA 608 standards.

UL 60335 is a general safety standard that applies to household and similar electrical appliances, including HVAC equipment. It sets basic safety requirements that manufacturers must meet to ensure their products are safe for consumer use. UL 60335-2-40 is a specific standard that deals with the safety of heat pumps and air conditioning equipment.

As part of complying with the new A2L requirements in UL 60335, units will use a Refrigerant Detection System (RDS). This system includes

A2L leak sensors certified to UL‑60335-2-40. When the system detects a leak, a mitigation sequence is initiated that includes the following mitigation actions:

- Energize the supply fan to deliver a required minimum amount of circulation airflow.

- Disable compressor operation.

- Provide an output to energize additional mechanical ventilation (if needed).

- Disable electric heat sources.

- Provide a 24V alarm dry contact to allow for external notification of leak detection.

- Dissipation system shall be “Fail Safe” per UL requirements. If a refrigerant sensor has a fault or is disconnected, the unit will initiate the mitigation actions.

Yes, the transition will affect maintenance practices. Technicians will need training to handle R-454B safely and to understand the nuances of the systems that use this new refrigerant. Additionally, there will be a need for new tools and servicing equipment.

There is a training available for flammable refrigerants that can be found with the Air Conditioning Contractors of America (ACCA) and by the North American Technician Excellence (NATE) in addition to other trainers.

As of March 2025, the ruling requiring a January 1st, 2025 changeover is unlikely to be changed, and even if the requirement was rescinded, essentially the entire comfort cooling industry has already transitioned to A2L refrigerants and a return to R-410A is extremely unlikely. The current discussions are more likely to impact refrigeration equipment used in the grocery store market which has compliance dates between 2026 and 2028. This does not apply to Airedale by Modine School IAQ products or the market we serve.