![]()

Helix™ Unit Controls

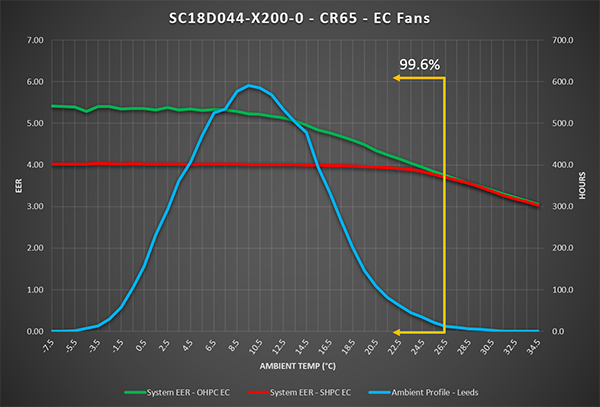

Optimised Head Pressure Control

A unique controls feature available to Chiller, Precision and Data Centre DX products, Optimised Head Pressure Control offers substantial energy savings.

In HVAC systems, head pressure is typically controlled during low ambient conditions by varying the amount of airflow through the condenser in order to prevent frozen evaporators, liquid-slugging in compressors, and low pressure cut-outs.

Rather than target a fixed head pressure setpoint during operation, a custom designed algorithm within the Helix product control system has the ability to vary head pressure dependent on load and in some cases, ambient. Efficiency is optimised by balancing condenser fan and compressor power consumption, resulting in a maximised system EER while guaranteeing cooling duty.

Typical energy savings using this ingenious controls feature on precision products can be up to 23%. For chillers with centrifugal or scroll compressors it can save in the region of 19% to 20%. The extent of energy saving is dependent on the product selection.

Our controls teams continuously work on our software platforms, optimising protocols to deliver enhanced features to our clients. For more information on why selecting an Airedale product keeps delivering long after the install date, contact our team.