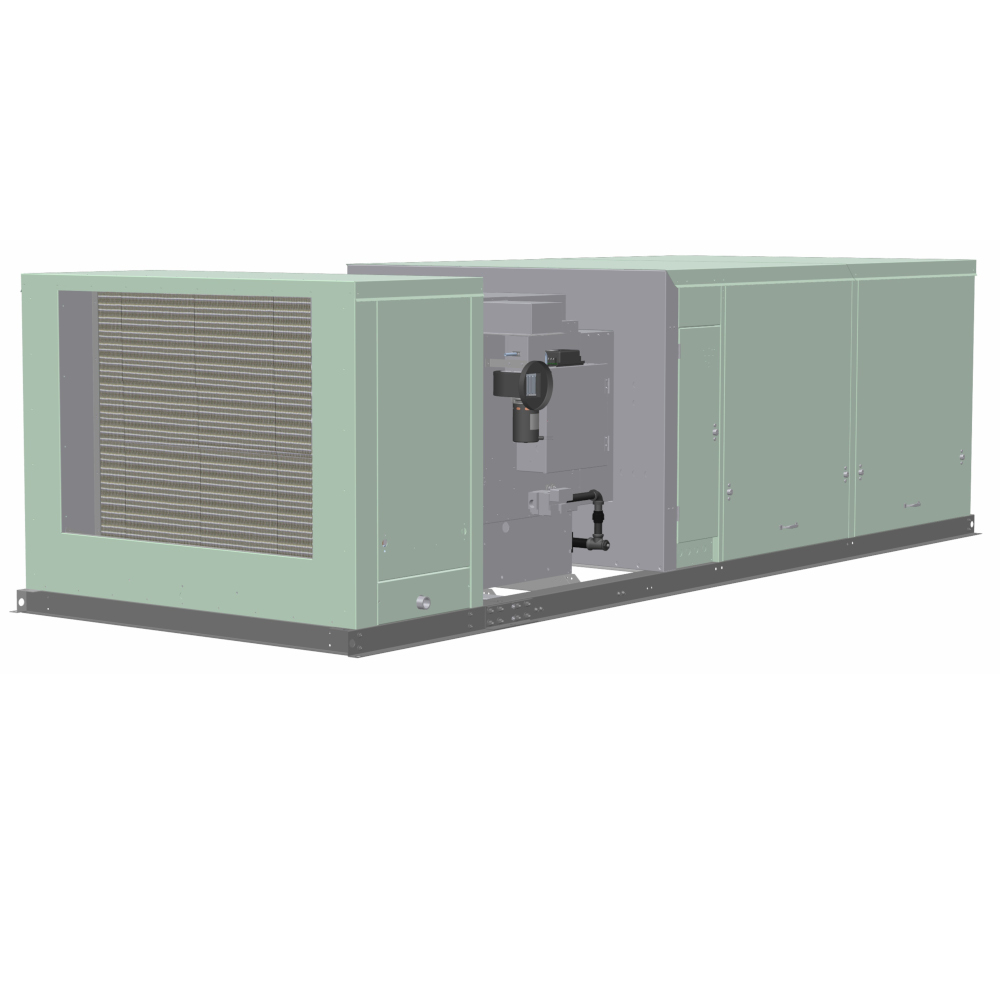

Indirect-Fired Outdoor Make-Up Air

Airedale offers a complete line of both indoor and outdoor indirect gas-fired heating and ventilating equipment in power and separated combustion venting configurations.

Depending on the requirements of the application, the duct furnace can be ordered either by itself, or with a blower section. If ordered with a blower section, a cooling coil section and/or a downturn can also be added to the configuration. With these configurations, the units can satisfy a building’s heating, make-up air, cooling, or ventilating requirements.

Indoor Power Vented Models: IBP/ICP

Indoor Separated Combustion Models: IBS/ICS

Outdoor Power Vented Modes: OBP/OCP/ODP/OPP

- Available in 16 model sizes with input ranges from 100,000 to 1,200,000 Btu/Hr.

- Airflow ranges from 750 to 14,500 CFM

- Natural or propane gas

- All units a minimum of 81% thermally efficient

- 20°-100°F air-temperature

- ETL certified

- Superior corrosion resistance and extended equipment life with 18-gauge, polyester-powder paint on an aluminized steel casing

- Blower and motor vibration isolation

- Blower performance up to 3.0” W.C. is perfect for longer ductwork or accessories with high-pressure drops

- Quick and accurate field connections with separate line and low-voltage terminal strips with job specific wiring diagrams

- UL60335 Compliant on system units that include a blower section

- 409 stainless steel heat exchanger, burner, and drip pan

- Two-stage and electronic modulation controls

- Modine Control System option provides a programmable microprocessor controller with building management compatibility

- High and/or low gas pressure switches

- Ultra-low leak class-I leakage resistance outside air dampers

- Two position, modulating, or floating building pressure control damper actuators maximizes control of outside ventilation air with fresh and return air dampers

- Variable frequency drives for maximum air volume control flexibility

- Factory-installed DX or chilled water coil

- Dead-front disconnect switches

- Double-wall construction for the blower and/or cooling cabinet

- Circuit analyzers minimize start-up and service time by immediately identifying causes of improper unit operation

- Smoke detectors, timed freeze protection, thermostats, time clocks, and many other control devices

- Roof curb and supply and/or return duct connectors to allow ductwork be field installed before unit arrives at the job site

Indirect Fired Duct Furnace and Make-Up Air Units Brochure

Gas-Fired Indirect Power-Vented Make-up Air Installation & Service Manual IBP/ICP

Gas-Fired Weatherproof Make-Up Air Units Installation & Service Manual OBP/OCP/ODP/OPP

Modine Control System Manual for Indirect Gas-Fired Heating and Make-Up Air Units