Environment

Airedale are known as a company that always tries to push the boundaries of technology, investing into research & development with a focus on energy efficiency and the environment.

Environmental Responsibilities

Air conditioning as an industry rightfully comes under pressure due to the refrigerant gases we use in our products. The unique properties of these gases mean they can absorb and reject heat easily and therefore be used to provide temperature management, not just for people, but for equipment that help the world function. There are life-saving and game-changing technologies in our day-to-day lives that require refrigeration and air conditioning to enable them to function properly, for example, hospital and laboratory equipment, and data centers. The world relies on air conditioning more than we realise.

F-Gas Directive

That said, many refrigerants are greenhouse gases that, if released into the atmosphere, contribute towards global warming. The European F-Gas directive, adopted by the European Union to phase-down the usage of refrigerants which have a high Global Warming Potential (GWP), is something we agree wholeheartedly with and have taken a proactive stance towards.

That said, many refrigerants are greenhouse gases that, if released into the atmosphere, contribute towards global warming. The European F-Gas directive, adopted by the European Union to phase-down the usage of refrigerants which have a high Global Warming Potential (GWP), is something we agree wholeheartedly with and have taken a proactive stance towards.

We take our environmental responsibilities seriously. For several years we have focused a large proportion our R&D resource on moving towards suitable replacements for refrigerants gases such as R410a and R134a. This development work started before the current F-gas regulations were introduced and started forcing the wider industry’s hand. This has helped create a level playing field in some respects but also helps us as a proactive business stay one step ahead. In 2014 we were one of the first companies to release a chiller with a R134a replacement (TurboChill range with R1234ze) and we have recently launched our R410A replacement chillers, the Ultima and DeltaChill ranges, both with R32 refrigerant.

Our Commitment

Airedale are also committed to using products that use less refrigerant gas, and employing technologies that ensure these gases do not reach the atmosphere. In our state-of-the art factory, the way we store and use gas is tightly regulated and controlled. We use smaller cooling coils called microchannels and use spray techniques in order to reduce the amount of gas we need to put in our products. We also try to minimize the amount of brazed joints in our pipework to reduce the risk of leaks occurring. We also offer leak detection systems and pump down facilities as standard that, should the worst occur, alert the equipment owner so mitigation can take place.

We are known throughout the industry as a company that always tries to push the boundaries of technology. We invest a large proportion of our profits back into research & development and in recent years this has been focused on producing products that are more energy efficient and which use lower amounts of refrigerants that are better for the environment. We are not at a state of utopia just yet, but we are getting there. And we will continue to work towards getting there.

Air conditioning is now a vital part of our day-to-day lives, we cannot function as a society without it. As a responsible corporate citizen, Airedale is committed to ensuring that the industry continues to support our day-to-day lives without harming the planet.

F-GAS

Airedale are committed to developing environmentally compliant products without compromising on performance.

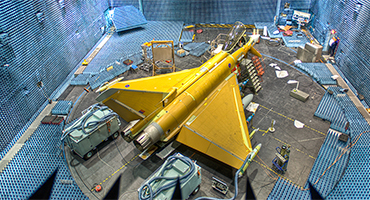

TEST CENTER

Airedale has invested in a multi-million pound 1,323m² purpose-built facility that sets the standard as one of the most advanced air conditioning product testing centers of its kind, and one of the biggest in Europe.

ENERGY & EFFICIENCY

The Ecodesign Directive is an approach to unit design which targets energy efficiency and lower carbon emissions.